Versión del blog en Español aquí

A short time ago, mu Prusa 2 had a setback where some of the parts broke in several pieces. Fortunately, I already knew this could happen and had an extra set of printed parts in case of something like this happened. I basically had to set up the printer from scratch, so I decided to make a good use of the opportunity and upgrade the printer to be able to use all the printing space. In the original design, the triangular frames are inside the Z motors, and it could happen that the X carriage with the extruder might collide with the frames. At the bottom of the printing space there's usually no problem because the bars are sufficiently separated from each other, but as the extruder goes up in the Z axis, the bars merge together, limiting the space in which the printer can move. This is why, instead of having a cubic printing space of 20x20x10 cm, what we have is a pyramidal printing space with a base of 20x20 cm and a height of 10 cm, and we don't want this. Here there are some examples of the motor colliding with one bar of the frame.

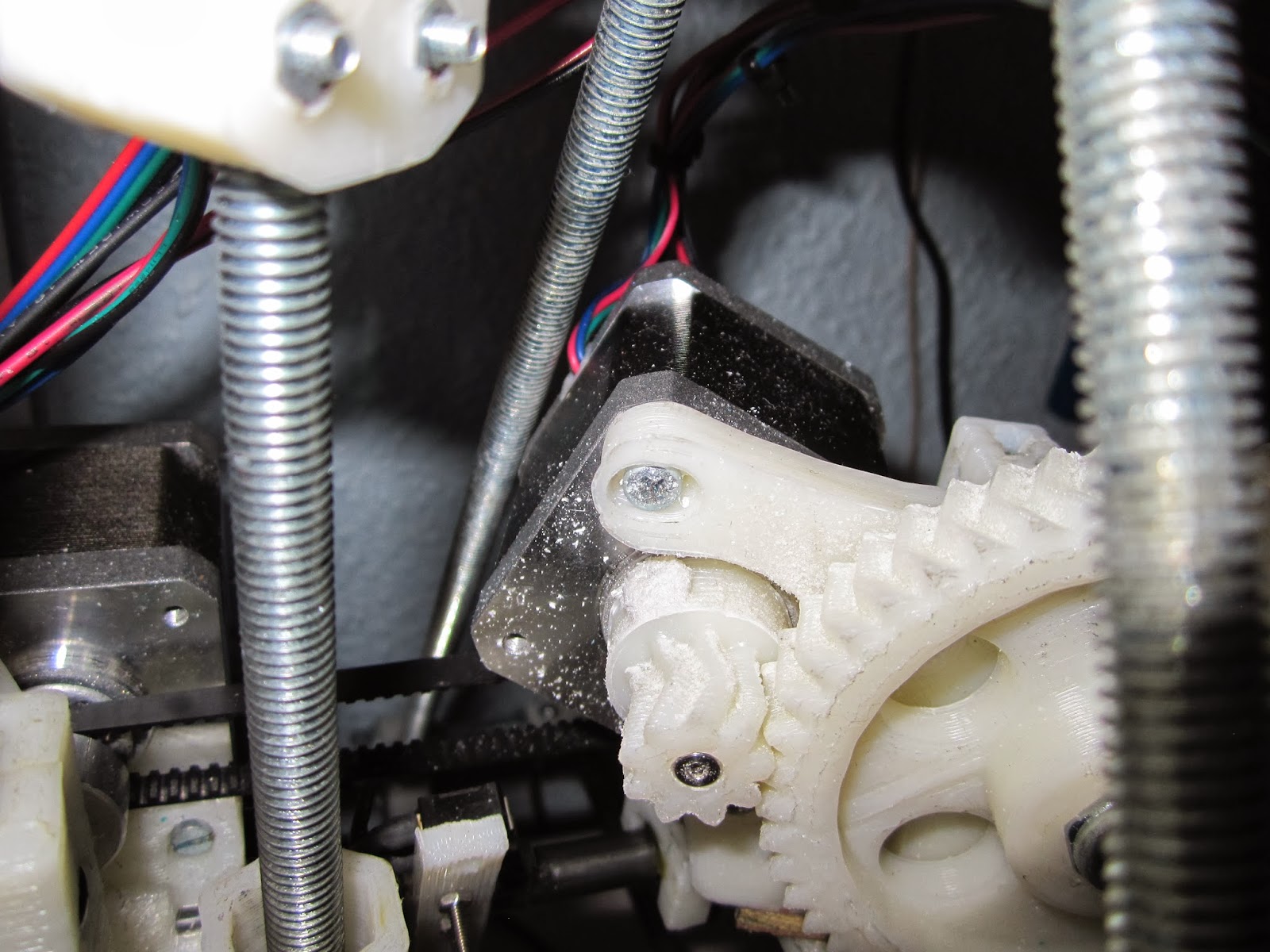

The solution was surprisingly easy. I just bought all the parallel bars to the X axis 50 cm in length, and this time I set up the motors for the Z axis inside the triangular frames. I also put two extra legs in the center of the structure to have more rigidity. This is the result: